CNC Tool Grinding Software

Price 3800000 INR/ Unit

CNC Tool Grinding Software Specification

- Rotation

- 360

- Product Type

- CNC Tool Grinding Software

- General Use

- Tool Grinding

- Material

- Steel

- Type

- Surface Grinding Machine

- Capacity

- Various

- Weight (kg)

- 800 kg

- Computerized

- Yes

- Automatic

- Yes

- CNC Or Not

- CNC

- Control System

- Fanuc

- Table Size

- 150 x 450 mm

- Table Slide Way

- V and Flat

- Magnetic Chuck Size

- 125 x 300 mm

- Grinding Wheel Size

- 180 x 13 x 31.75 mm

- Grinding Wheel Speed

- 2850 rpm

- Grinding Length

- Max. 300 mm

- Floor Space

- 950 x 800 x 1300 mm

- Fuel Tank Capacity

- 60 liters

- WorkingSpeed

- Variable

- Spindle Speed

- 3600 rpm

- Power

- 3 HP

- Voltage

- 415 V

- Dimension (L*W*H)

- 950 x 800 x 1300 mm

- Feature

- High Precision, Easy Operation

- Color

- White

CNC Tool Grinding Software Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 1 Week

About CNC Tool Grinding Software

CNC Tool Grinding Machine

From our extensive range of machinery, we manufacture, export and supply supreme quality CNC Tool Grinding Machine. For the manufacturing of this machine, our professionals use superior quality components and pioneering technology in sync with the defined international standards. Specially designed to bend stiff and hard material pipes into small radius with ease, the offered CNC Tool Grinding Machine is available in varied models and specifications as per the application requirements of customers at reasonable rates.

Features of CNC Tool Grinding Machine :

- Fully automatic

- Easy operation

- User friendly applications

- Long service life

Model - NCW300 - 3 Axis

The CNC Tool Grinding Machine NCW 300 -3 Axis is designed for wide range of application with 3 axis CNC movement, combined with 9 manually adjustable rotating and Swivel axis, solve almost all grinding requirement. All movements are fully automatic and one operator can load several machines. Easy operation is ensured by user friendly menus, for flute, peripheral, radius taper or cylindrical grinding. In addition the spiral leads are measured with an electronic measuring probe and recorded in the control. The 3-D continuous path control with graphic display is also freely programmable and tooling data is entered vis ISO standard code to DIN 66025

Simple input of grinding data with the help of direct operator dialogue, no programming knowledge is required. Short setup times and possibilities for greater economy and high grinding quality. regrinding made possible by repeatable, accurate and quick measuring of spiral lead by means of electronic measuring probe. Variable adjustable rotary and swivelling axis bring the work head in any required ( vertical or horizontal axis, up or down, left or right ) against the grinding spindle axis.

| | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| | | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Streamline Your Tool Grinding Workflow

Designed for CNC surface grinding machines, this software simplifies complex grinding operations. Automatic controls, variable speed adjustments, and Fanuc integration contribute to a user-friendly experience. Operators benefit from improved accuracy and reduced manual intervention, making it ideal for high-volume production and precision tool refurbishment.

Precision and Efficiency, Redefined

Leverage the high-precision capabilities of the CNC Tool Grinding Software to achieve consistent results across multiple steel tool types. With a robust design and advanced computerized features, surface grinding tasks are performed swiftly, enhancing productivity without compromising on quality or safety.

Flexible and Scalable Applications

Adaptable for various industry use-cases, the software supports flexible grinding parameters and table movements. The generous floor space and fuel tank capacity allow for extended operation times, making it suitable for environments that demand endurance and scalability. Whether for manufacturing, servicing, or trading, it accommodates diverse operational needs.

FAQs of CNC Tool Grinding Software:

Q: How does the CNC Tool Grinding Software improve grinding precision?

A: The software leverages Fanuc-controlled automation and computerized settings to ensure uniform grinding patterns, consistently achieving high-precision results on steel tools. Automated adjustments minimize human error and optimize surface finish quality.Q: What types of grinding operations can I perform with this system?

A: You can carry out a variety of grinding tasks including surface grinding, tool reshaping, and precision finishing. The software accommodates different wheel and table settings for diverse tool geometries and sizes, with maximum grinding length of 300 mm.Q: When is the best time to utilize automatic and variable speed features?

A: Automatic and variable speed features are particularly beneficial when processing high-volume batches or working with materials requiring specific surface finishes. These functions help optimize cycle times while maintaining accuracy.Q: Where can the CNC Tool Grinding Software be deployed effectively?

A: It is ideal for use in manufacturing plants, service centers, tool refurbishment units, and trading facilities. Its compact dimensions (950 x 800 x 1300 mm) allow for easy installation in both small and large industrial workshops.Q: What is the typical process flow when using this tool grinding software?

A: Operators begin by configuring grinding parameters on the CNC interface, selecting the appropriate wheel speed, spindle speed, and table movement. Upon activation, the software manages the grinding cycle, ensuring precise and consistent results through real-time automation.Q: How does utilizing this software benefit my operation in terms of productivity and maintenance?

A: The system enhances productivity by automating grinding cycles and reducing manual intervention. High grinding speeds and precise controls enable faster turnaround with less wear-and-tear, lowering maintenance costs over time.Q: Can this grinding software handle various steel tool sizes and shapes?

A: Absolutely, the flexible table and magnetic chuck sizes, combined with adjustable software settings, allow grinding of tools with diverse dimensions and profiles, supporting a wide range of steel materials commonly used in the industry.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Tool Grinding Machine Category

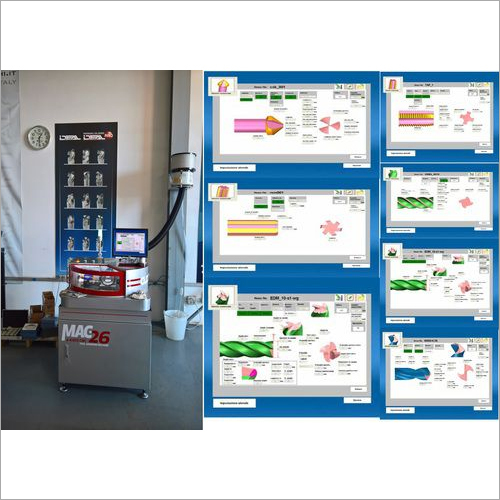

MAC26 CNC tool grinding Machine

Price 2676888 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : tool resharpaning

Feature : ECO Friendly

Automatic : Yes

Warranty : Yes

MAC 26 Tool Regrinding Machine

Price 2900000 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Feature : ECO Friendly

Automatic : No

Warranty : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS